-

Products

- Acoustic Guitar Strings

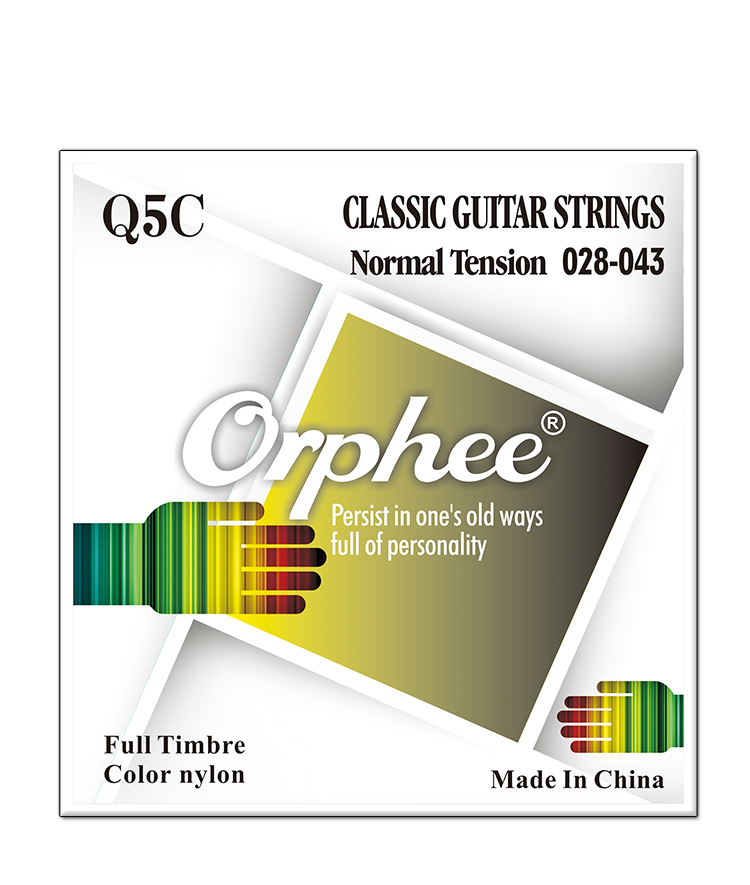

- Classical Guitar Strings

- Electric Guitar Strings

- Ukulele Strings

- Electric Bass Guitar Strings

- Other Strings

-

SA Strings

-

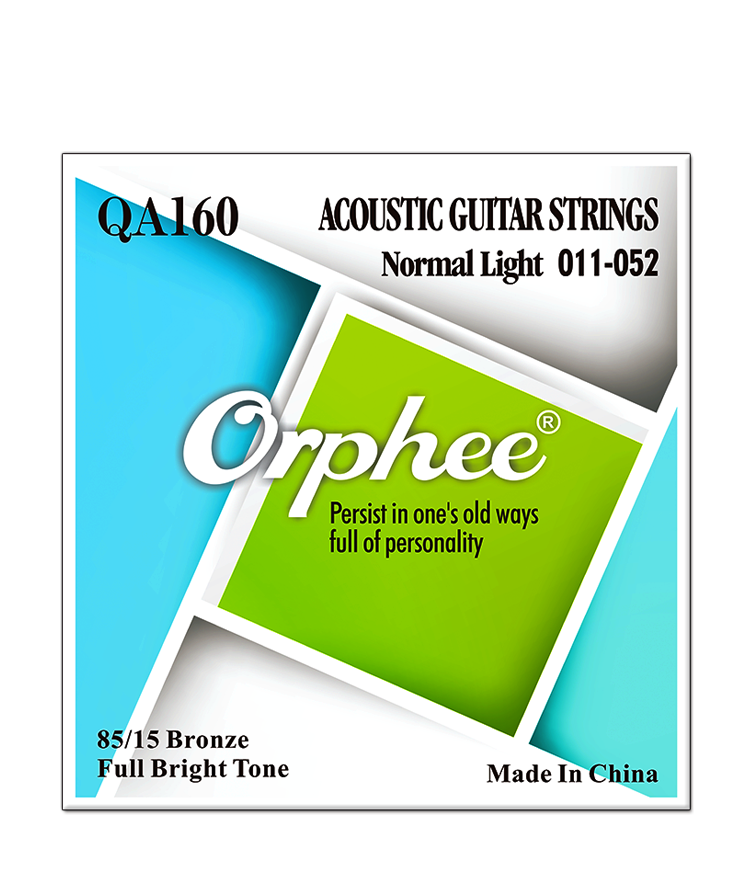

QA Strings

-

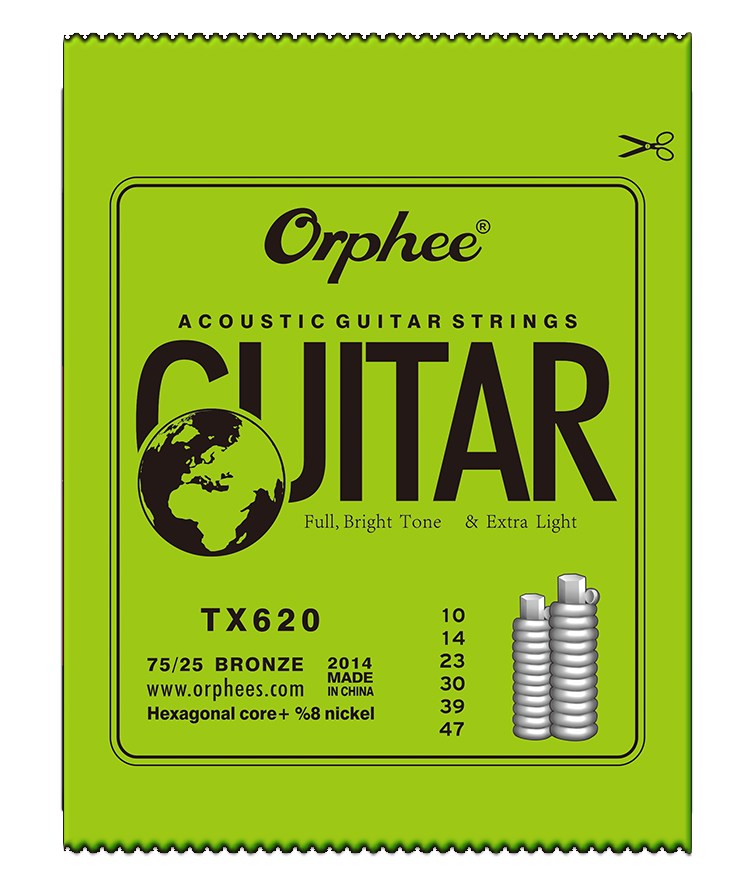

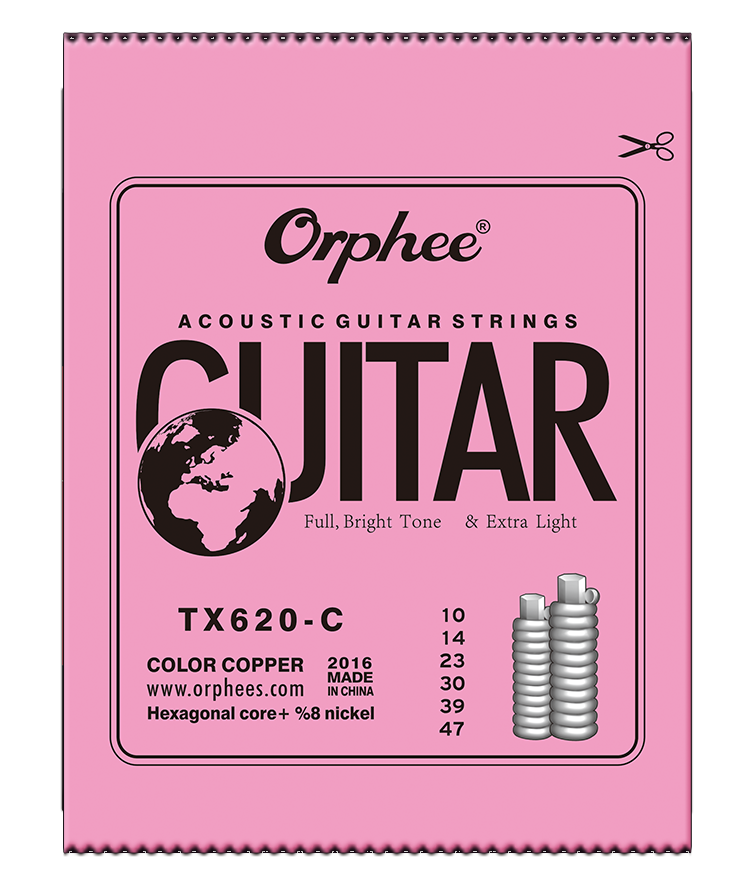

TX Strings

-

SC Strings

-

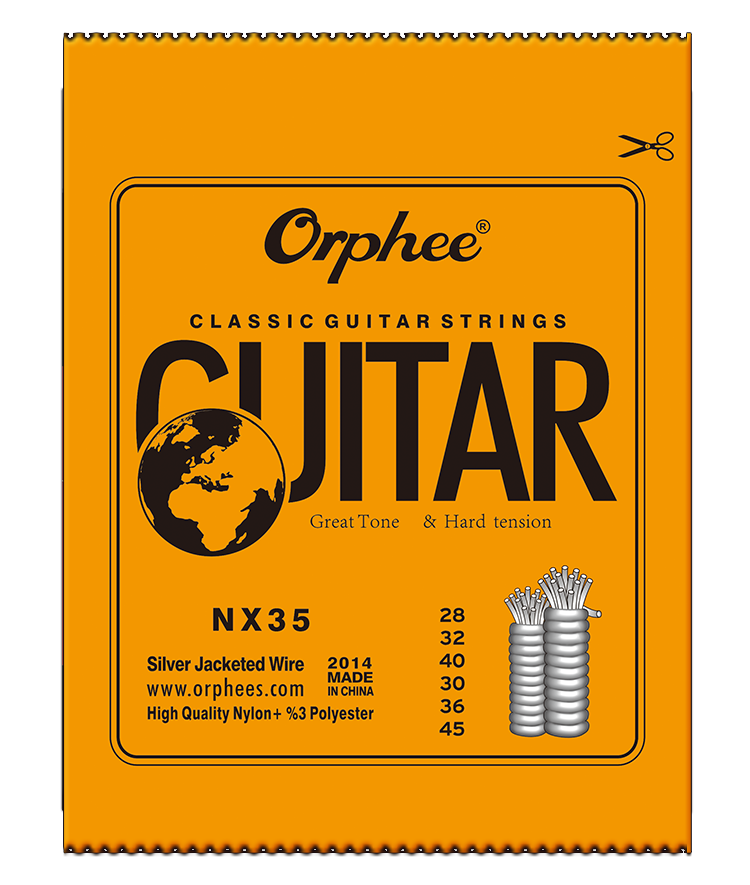

NX Strings

-

SE Strings

-

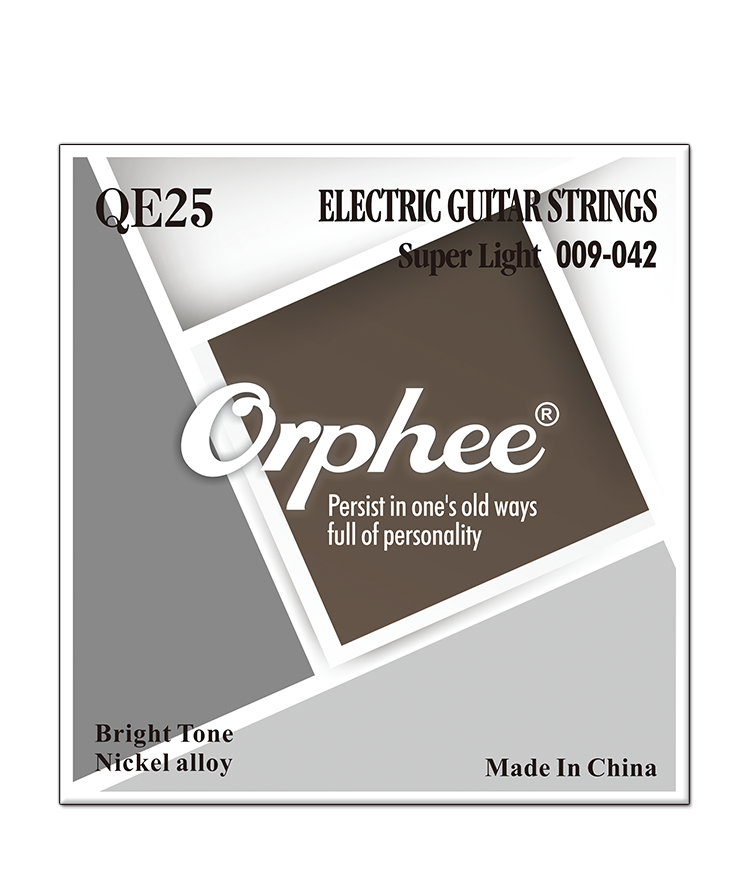

QE Strings

-

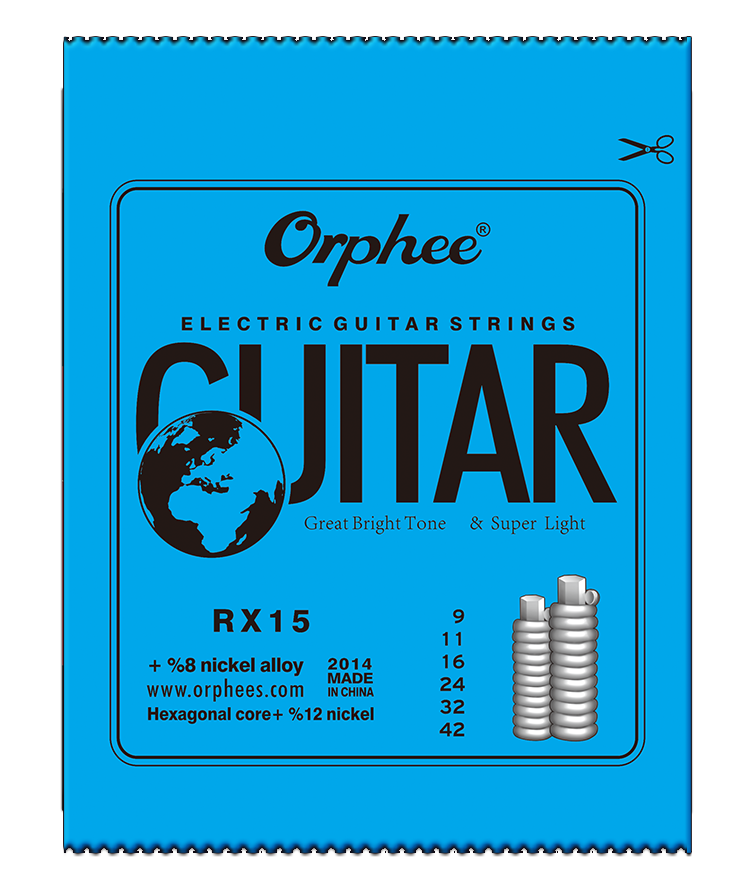

RX Strings

-

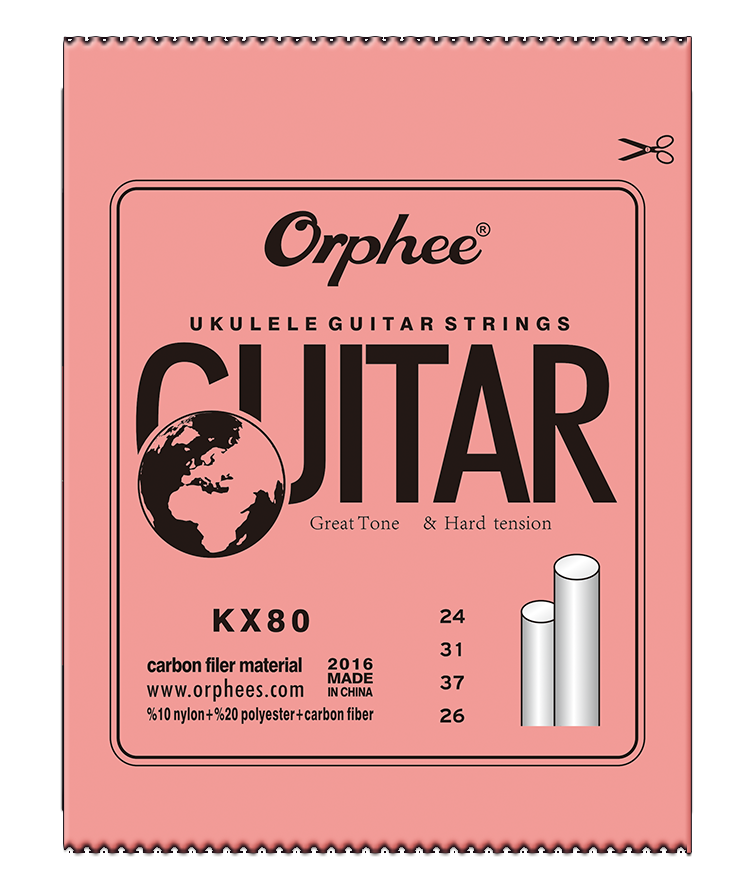

KX Strings

-

SU Strings

-

QK Strings

-

SB Strings

-

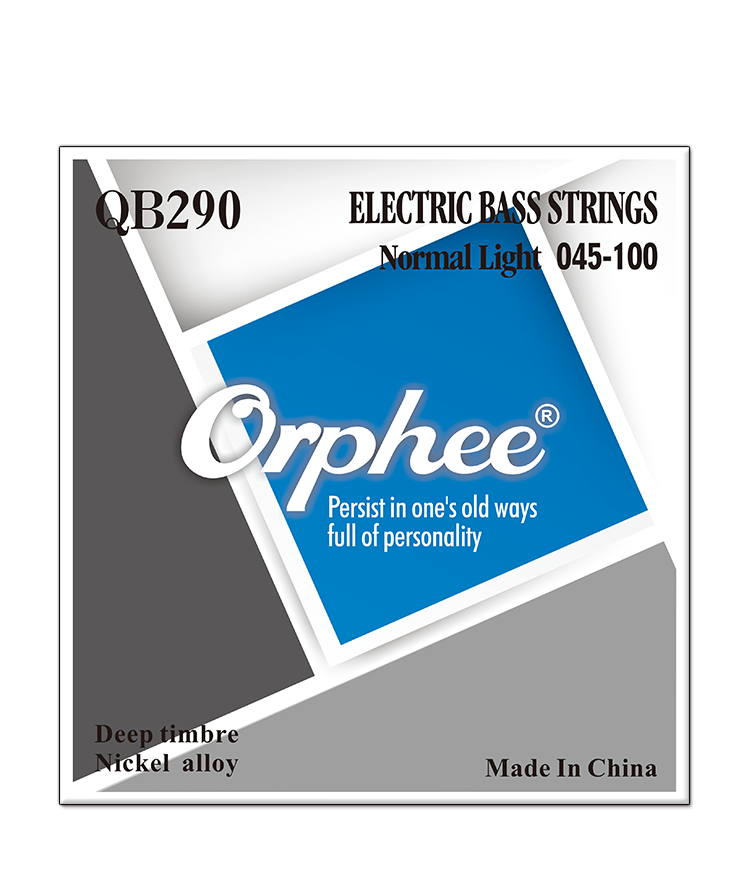

QB Strings

-

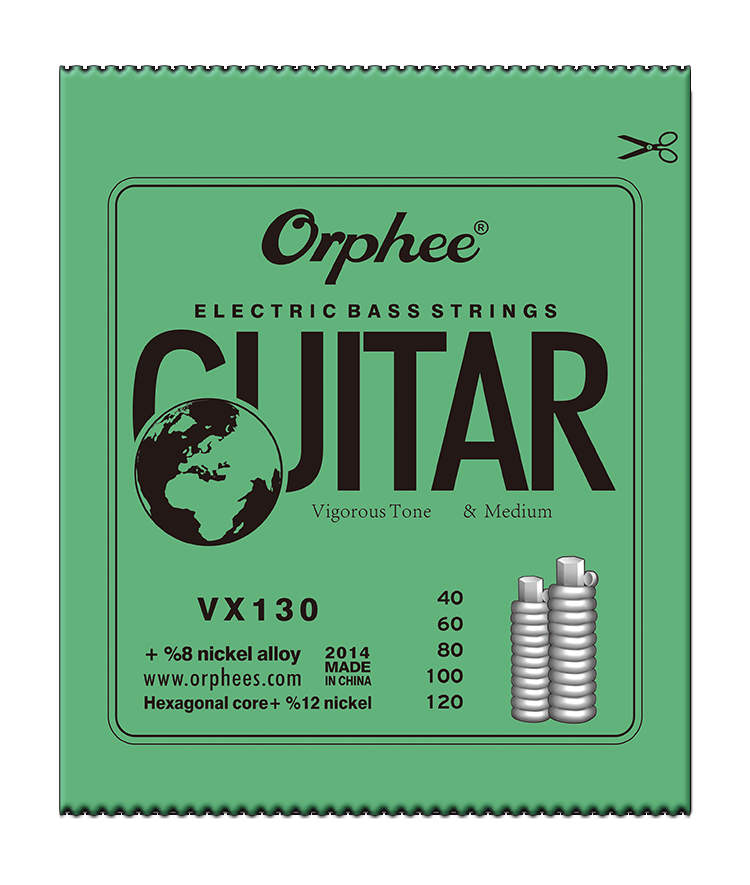

VX Strings

-

Guitar Capo

-

Q Series

-

Audition Center

-

Musicians

-

Xiang Wei

Daxiang (Xiangwei) Li Jian Singer Exclusive Guitarist Famous guitarist / Music producer / Ukulele performer Won the First place Finger China Forum Arranger

-

Hu Sir

CEO of China Guitar Expert Musician / Senior Guitar Lecturer 15 years of full-time guitar teaching

-

Sai Ping

Professional media player for guitar assessment.Member of Jiangsu Liuxian Music Association. Judges of the WAGF Fingerstyle Family Competition and Kepma Guitar Competition.Founder of Flying Musical. Founder and lecturer of advanced guitar teaching

-

Mo Siyi

The new voice Finger guitar goddess Corbin Cup National Championship at the 16th China Guitar Art Festival Vice President Guitar Association of Maoming City Executive Vice Chairman of China (Zhuhai) Guitar Art Festival Image Consultant of Zhongshan Pop Music Association

-

Chen Xi

Chinese guitar player Visiting Professor of Honghe Music and Dance college

-

-

About Us

-

News

-

Contact Us

0752-3355476

0752-3355476

购买

购买